All about our Lightweight Tent Pegs

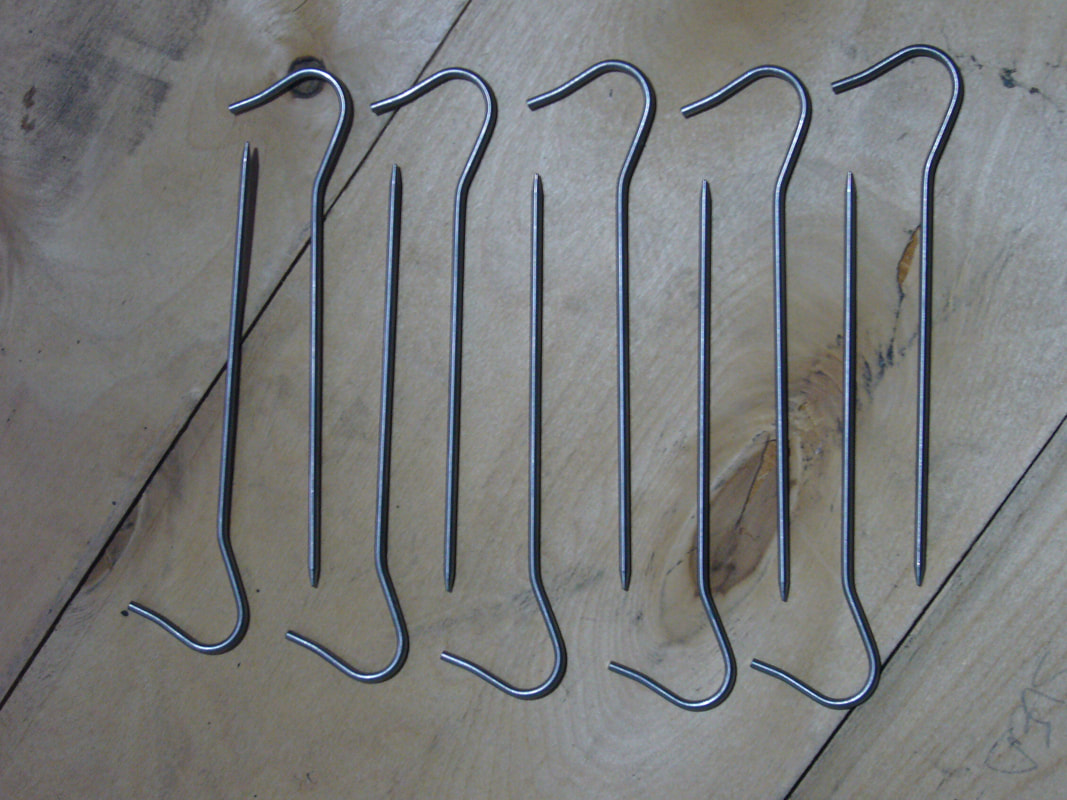

The tents that we supply come as standard with lightweight aluminium tent pegs. These aluminium tent pegs are either V-shape (otherwise called V-section tent pegs), Y-shape (Y-section), or candy cane shape, depending on which tent you are buying. All of our tents also come with the option of Superlite titanium classic shepherd’s crook tent pegs.

We also have a variety of other pegs that can be bought separately in packs, such as our aluminium needle pegs and out titanium nail (or rock) pegs.

We also have a variety of other pegs that can be bought separately in packs, such as our aluminium needle pegs and out titanium nail (or rock) pegs.

Click on the appropriate links below to go directly to out lightweight tent peg products:

Superlite Titanium Tent Pegs

Lightweight Aluminium Tent Pegs

Superlite Titanium Tent Pegs

Lightweight Aluminium Tent Pegs

Of course heavy steel tent pegs have their place, they can be made large, strong and are relatively cheap, and they may be very suitable for pegging out large heavy family tents. However, for lightweight camping, steel tent pegs are often unsuitable due to their relatively heavy weight. Lighter steel tent pegs for small tents tend to be weak and very prone to bending, so aluminium and titanium are the much preferred material for lightweight tent pegs.

Aluminium vs Titanium

Many people assume that titanium is lighter than aluminium, when in fact it is not. For equal volumes of metal, aluminium weighs one third that of steel, whereas titanium weighs half that of steel. Unlike steel, both metals are corrosion resistant, with titanium being far superior to aluminium in this respect. However, both aluminium and titanium have very different properties, which I will elaborate on shortly. Many people also assume that titanium tent pegs are indestructible and don't expect them to flex - they are not, and they do.

The fact is, any tent peg will bend or break if you try forcing it hard against a stone or rock in the ground with either your boot, or hammering it in with a brick... something has to give and it won't be the stone or rock! It should be obvious that these relatively thin metal spikes have their limitations, but many people don't seem to realise or recognise this. Where possible tent pegs should be eased and teased into the ground in a controlled manner by hand, or gently tapped in with a lump of wood or a small rock, you simply cannot stomp on a tent peg from a great height with size 12 walking boots, and expect the tent peg to come out unscathed! You also have far less control when stamping on a tent peg with your boot than you do if you are carefully tapping it into the ground by hand with a small rock.

Titanium is stronger than aluminium, so tent pegs can be made of less material and hence can be made lighter. But it is not all about tensile strength. For example one of our 9.5 gram aluminium alloy needle tent pegs is far harder, far more rigid than one of our 5 gram shepherd’s crook titanium tent pegs, but once the aluminium alloy has bent or kinks then it is very hard to reshape, and in doing so it can suffer metal fatigue that will cause it to weaken and possibly fail completely in time. Conversely titanium tent pegs will flex and bend far easier than their aluminium counterparts, but they do not tend to kink like aluminium (or steel) and can be reshaped quite easily and without suffering the same extreme metal fatigue. In short titanium is far more malleable. The flexibility of our 5 gram (3mm) Superlite classic shepherd's crook titanium tent pegs means that they can twist and flex past obstacles in stony ground far easier than the more rigid aluminium tent pegs, so as always with these things there are pros and cons. And, just like tents themselves, there is no universally fantastic, all-purpose tent peg. That is to say, there is no tent peg that will excel in every possible condition or every possible environment.

Steel tent pegs are heavy and will corrode (rust) quite readily, and whilst they do not suffer from quite the same metal fatigue as aluminium when they have bent or kinked, they are still far harder to reshape than titanium.

The fact is, any tent peg will bend or break if you try forcing it hard against a stone or rock in the ground with either your boot, or hammering it in with a brick... something has to give and it won't be the stone or rock! It should be obvious that these relatively thin metal spikes have their limitations, but many people don't seem to realise or recognise this. Where possible tent pegs should be eased and teased into the ground in a controlled manner by hand, or gently tapped in with a lump of wood or a small rock, you simply cannot stomp on a tent peg from a great height with size 12 walking boots, and expect the tent peg to come out unscathed! You also have far less control when stamping on a tent peg with your boot than you do if you are carefully tapping it into the ground by hand with a small rock.

Titanium is stronger than aluminium, so tent pegs can be made of less material and hence can be made lighter. But it is not all about tensile strength. For example one of our 9.5 gram aluminium alloy needle tent pegs is far harder, far more rigid than one of our 5 gram shepherd’s crook titanium tent pegs, but once the aluminium alloy has bent or kinks then it is very hard to reshape, and in doing so it can suffer metal fatigue that will cause it to weaken and possibly fail completely in time. Conversely titanium tent pegs will flex and bend far easier than their aluminium counterparts, but they do not tend to kink like aluminium (or steel) and can be reshaped quite easily and without suffering the same extreme metal fatigue. In short titanium is far more malleable. The flexibility of our 5 gram (3mm) Superlite classic shepherd's crook titanium tent pegs means that they can twist and flex past obstacles in stony ground far easier than the more rigid aluminium tent pegs, so as always with these things there are pros and cons. And, just like tents themselves, there is no universally fantastic, all-purpose tent peg. That is to say, there is no tent peg that will excel in every possible condition or every possible environment.

Steel tent pegs are heavy and will corrode (rust) quite readily, and whilst they do not suffer from quite the same metal fatigue as aluminium when they have bent or kinked, they are still far harder to reshape than titanium.

Lightweight Aluminium Needle Tent Pegs (9.5g) - Superlite Titanium Shepherd's Crook Tent Pegs (5g)

Tent Peg Styles

A smooth round tent peg will much easier pull out of soft ground than a V-section peg which is designed to hold more ground. However, by their very nature V-section tent pegs can be much harder to push into firmer or stony ground. The V-section tent pegs are less prone to bend or kink than round tent pegs, but any tent peg can be bent or destroyed by applying too much brute force. Generally speaking you will find that the tent pegs that come as standard with your tent will be quite adequate in most situations. Only extreme situations may call for a different type of tent peg. For example, camping on a beach would certainly require a tent peg that could hold a lot of ground. In such circumstances our Superlite titanium shepherd’s crook tent pegs would likely be totally useless, and this would be where large, wide, V-section tent pegs would come into their own.

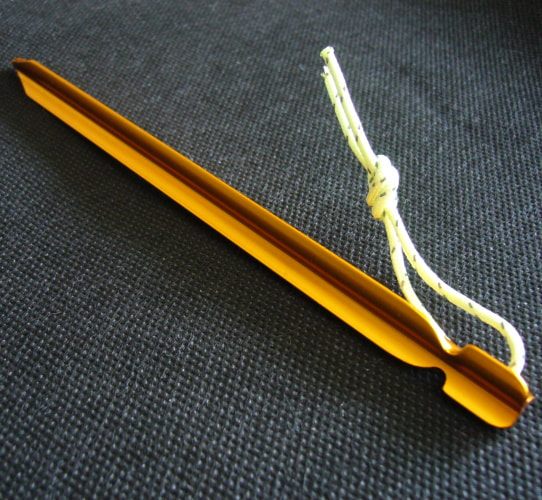

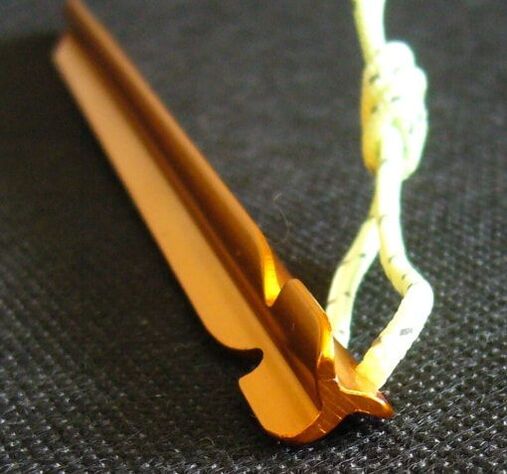

A compromise between the round wire tent pegs and the standard V-section tent pegs are the square needle tent pegs. The ones that we supply are made from tough, aviation grade anodised aluminium and are 160mm long and 5mm x 4mm wide. The rectangular shape makes them less prone to twisting on there axis than round tent pegs.

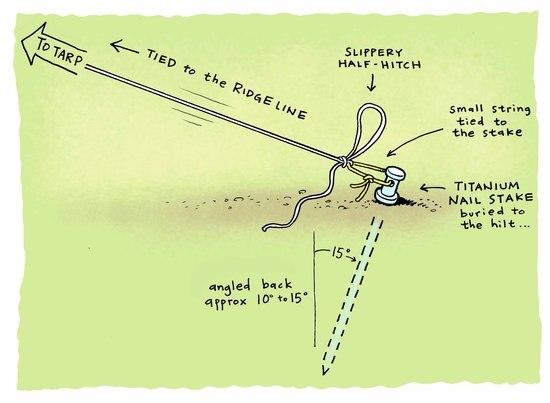

For very hard or stony ground you may require rock pegs (otherwise known as nail pegs). These are usually thicker than other tent pegs with a flat head - like a nail - that allows you to literally hammer them into the ground with a rock or a hammer. But do bear in mind, if you use a 8lb lump hammer to insert them into rocky ground, then they can be a real bugger to get out again. Also bear in mind that nail-type rock pegs do not feature any natural hook in which to loop a guyline over, so the angle you hammer them into the ground is particularly important if you intend to simply loop your guyline around them. If you are just looping your guyline around them, then loop it a couple of times and make sure the tent pegs are inserted into the ground at such an angle that the guyline won't easily slip over and off. You can instead use a tight knot around the nail tent peg, such as a Slippery Hitch Knot or attach the guyline directly to the pull loop with a suitable knot. A very useful knot for attaching the guyline directly to the pull loop is a Slippery Half Hitch Knot as shown below or the adjustable Tautline Hitch which will do away with the need for the guyline tensioner.

A compromise between the round wire tent pegs and the standard V-section tent pegs are the square needle tent pegs. The ones that we supply are made from tough, aviation grade anodised aluminium and are 160mm long and 5mm x 4mm wide. The rectangular shape makes them less prone to twisting on there axis than round tent pegs.

For very hard or stony ground you may require rock pegs (otherwise known as nail pegs). These are usually thicker than other tent pegs with a flat head - like a nail - that allows you to literally hammer them into the ground with a rock or a hammer. But do bear in mind, if you use a 8lb lump hammer to insert them into rocky ground, then they can be a real bugger to get out again. Also bear in mind that nail-type rock pegs do not feature any natural hook in which to loop a guyline over, so the angle you hammer them into the ground is particularly important if you intend to simply loop your guyline around them. If you are just looping your guyline around them, then loop it a couple of times and make sure the tent pegs are inserted into the ground at such an angle that the guyline won't easily slip over and off. You can instead use a tight knot around the nail tent peg, such as a Slippery Hitch Knot or attach the guyline directly to the pull loop with a suitable knot. A very useful knot for attaching the guyline directly to the pull loop is a Slippery Half Hitch Knot as shown below or the adjustable Tautline Hitch which will do away with the need for the guyline tensioner.

BELOW: V-Section Anodised Aluminium Tent Pegs

ABOVE: Curved Y-Section Anodised Aluminium Tent Pegs

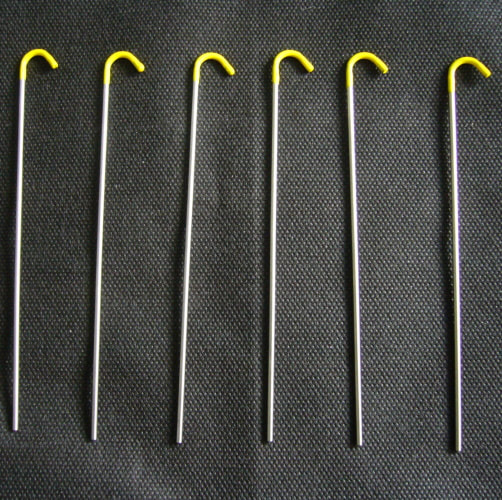

BELOW: Ultralite 2g Titanium Hook Pegs

In ideal weather and ground conditions, small (130mm x 2mm) Ultralite 2 gram titanium hook pegs can work effectively and obviously offer a great weight-saving, however they do not provide a great deal of holding power. So in anything less than ideal weather and ground conditions their effectiveness will certainly be suspect. Generally speaking they are really only suitable for holding a groundsheet in place as they will not hold in most ground sufficiently well when under load. That said, in order to save weight you can very effectively use them to peg down the inner tent as long as the outer flysheet has ample pegging points (and preferably as long as the inner tent is not sharing the pegging points with the outer tent as with many modern tents - and indeed the tents that we supply). For pinning down an additional ground sheet or footprint they are ideal (as long as the ground will take them).

All this said, ultralight campers and backpackers may opt for these 2g Ultralite titanium tent pegs to peg down their entire tent or tarp (usually placing rocks on top of load bearing pegs to aid their ground retention), but we personally would never consider using them for pegging down a flysheet.

To all intents and purposes the even lighter 1 gram titanium hook tent pegs that are (believe it or not) provided with some of the very high-end, super-expensive tents in order to keep their total tent package weight down, are just mind-bogglingly ridiculous - effectively just a bit of bendy wire, and totally, utterly useless in the real world... though they may be helpful in removing that irritating, stubborn piece of cabbage stuck between your teeth!

All this said, ultralight campers and backpackers may opt for these 2g Ultralite titanium tent pegs to peg down their entire tent or tarp (usually placing rocks on top of load bearing pegs to aid their ground retention), but we personally would never consider using them for pegging down a flysheet.

To all intents and purposes the even lighter 1 gram titanium hook tent pegs that are (believe it or not) provided with some of the very high-end, super-expensive tents in order to keep their total tent package weight down, are just mind-bogglingly ridiculous - effectively just a bit of bendy wire, and totally, utterly useless in the real world... though they may be helpful in removing that irritating, stubborn piece of cabbage stuck between your teeth!

Titanium Tent Pegs

12g V-Section Peg - 2g Hook Peg - 5g Shepherd's Crook Peg - 10g Rock Tent Peg (Nail Peg)

12g V-Section Peg - 2g Hook Peg - 5g Shepherd's Crook Peg - 10g Rock Tent Peg (Nail Peg)