****** Available NOW *****

STATION13 - Tent Pole Repairs

Replacement Tent Poles, Spares & Fittings

We are now in a position to be able to provide replacement tent poles and various associated fittings.

These Replacement Tent Poles & Fittings are available now from our eBay shop

Just CLICK below to go directly to our STATION13 eBay listings

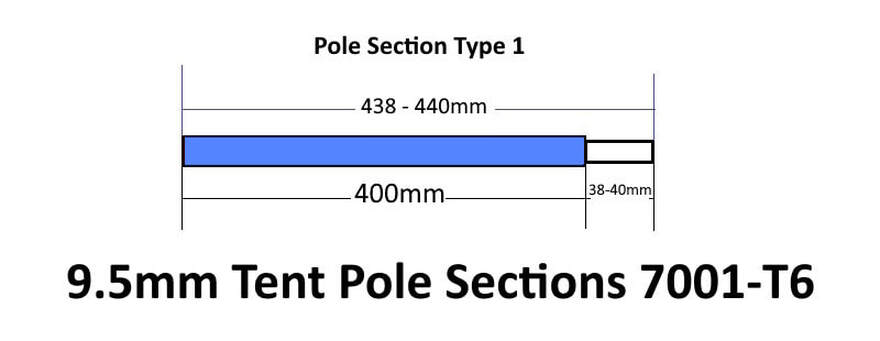

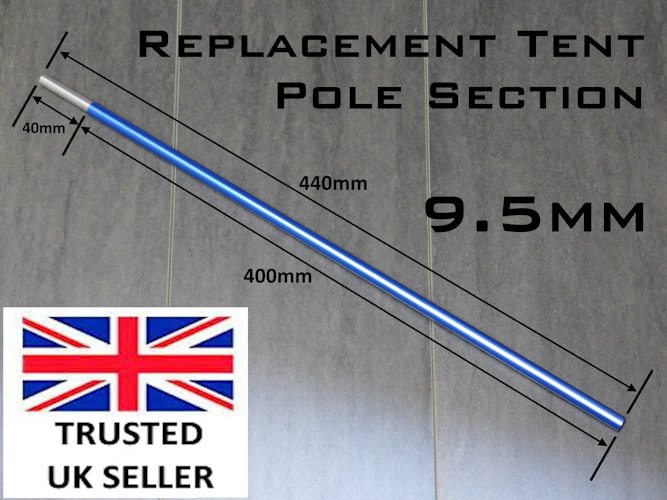

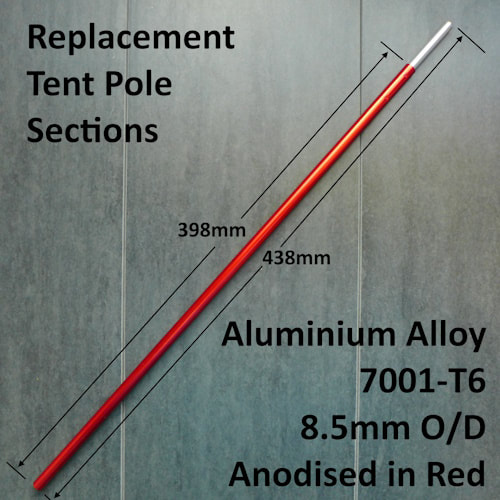

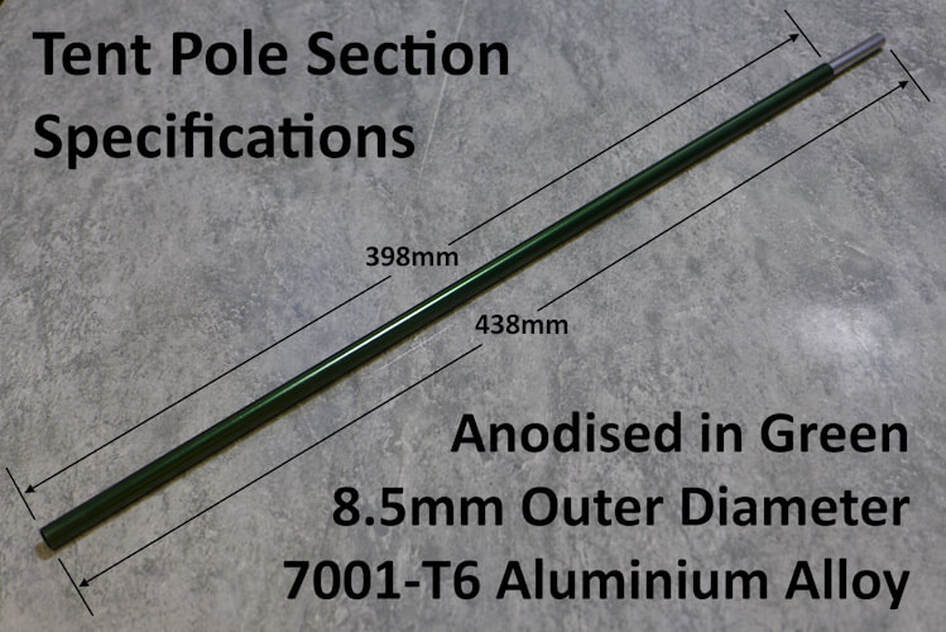

8.5mm Tent Poles 9.5mm Tent Poles

or simply click on the IMAGES

This means, not only will we be able to provide replacement poles for our own tents, but we will also be able to provide replacement tent poles for many tents requiring 8.5mm and 9.5mm tent poles. We plan to provide replacement 8.5mm and 9.5mm tent poles not only in set lengths but also in custom lengths to suit individual requirements. However, we will only be supplying straight tent poles and straight tent pole sections; that is, we do not have the tools necessary to provide pre-bent or curved tent pole sections.

Though we understand that some tents use odd sizes, such as 8.7mm and 9mm outer diameter tent poles, 8.5mm and 9.5mm are by far the most common standard size tent pole used in the majority of one and two person backpacking tents, with 8.5mm often used as an upgrade to replace many of the thinner 7.9mm tent poles.

UPDATE: We now have 9.5mm aluminium alloy 7001-T6 Pro-Flex tent poles in stock at our eBay shop. HERE or click the images below.

These Replacement Tent Poles & Fittings are available now from our eBay shop

Just CLICK below to go directly to our STATION13 eBay listings

8.5mm Tent Poles 9.5mm Tent Poles

or simply click on the IMAGES

This means, not only will we be able to provide replacement poles for our own tents, but we will also be able to provide replacement tent poles for many tents requiring 8.5mm and 9.5mm tent poles. We plan to provide replacement 8.5mm and 9.5mm tent poles not only in set lengths but also in custom lengths to suit individual requirements. However, we will only be supplying straight tent poles and straight tent pole sections; that is, we do not have the tools necessary to provide pre-bent or curved tent pole sections.

Though we understand that some tents use odd sizes, such as 8.7mm and 9mm outer diameter tent poles, 8.5mm and 9.5mm are by far the most common standard size tent pole used in the majority of one and two person backpacking tents, with 8.5mm often used as an upgrade to replace many of the thinner 7.9mm tent poles.

UPDATE: We now have 9.5mm aluminium alloy 7001-T6 Pro-Flex tent poles in stock at our eBay shop. HERE or click the images below.

Our replacement tent poles are ProFlex poles made from aluminium alloy 7001 and tempered to T6 standard. 7001-T6 aluminium alloy is generally regarded as the best aluminium alloy for lightweight tent poles, providing the best balance between weight and strength. This aluminium alloy is pretty much the standard used in all high quality, high end tents, including such as Terra Nova and Hilleberg, which use Korean company DAC tent poles. That said, DAC do however use their own proprietary derivative of 7001 aluminium alloy tempered to T8 (TH72M) for their tent poles.

In reality the performance difference between DAC’s 7001-T8 aluminium alloy and the more standard 7001-T6 aluminium alloy is marginal, and in more cases than not, the less costly standard 7001-T6 aluminium alloy will perform equally as well under most conditions. 7001-T6 is used in the manufacture of tent poles because it has an excellent strength to weight ratio and a high yield rate – that is the amount it can flex before being permanently deformed.

The odd tent brand may use 7075 aluminium alloy for its tent poles, which is an inherently stiffer alloy than 7001, so will not deflect as much under duress. However, this property also makes for a more brittle tent pole. So although it may be more rigid, it will more likely fracture than flex in more extreme weather conditions. Our aluminium trekking poles are made from 7075 aluminium alloy, as rigidity is more important than flex in a trekking pole (STATION13 trekking Poles). Our trekking poles are of course also fabricated from substantially thicker and stronger aluminium tubing than that of tent poles.

Be aware, some cheaper tents may also use 6000 series aluminium alloy tent poles. This is a less costly aluminium alloy, but it is inherently weaker than 7000 series aluminium alloy when used for tent poles. 6000 series alloy tends to have much less flex and be far more rigid, so again, more likely to fracture or snap than flex when stressed. By way of emphasising this, most lightweight aluminium tent pegs are made from 6000 series aluminium alloy, as are many aluminium bicycle frames, where the greater flex of 7000 series aluminium alloy would be less desirable.

We looked long and hard at the pros and cons of various alloys but ultimately we settled on 7001 alloy, because even if a tent pole was to flex to a point that it became slightly deformed, we see this as a better option than it fracturing or completely snapping, which may be far more likely with 7075 alloy. And, after all, if DAC are happy with 7001 aluminium alloy, then who are we to argue.

Now, whereas the likes of DAC manufacture various versions of lightweight tent poles, using varied manufacturing techniques to add strength, or to shave off grams here and there in order to reduce the overall weight of their poles, we have stuck to the more universal tent pole construction.

By this I mean that our ProFlex tent poles use a standard aluminium press-fit insert to connect one pole to the next. And unless your tent poles are manufactured by DAC, Easton or Yunan (that may use a different connecting method, and/or be of an odd size), then your tent poles will very likely be the same.

In reality the performance difference between DAC’s 7001-T8 aluminium alloy and the more standard 7001-T6 aluminium alloy is marginal, and in more cases than not, the less costly standard 7001-T6 aluminium alloy will perform equally as well under most conditions. 7001-T6 is used in the manufacture of tent poles because it has an excellent strength to weight ratio and a high yield rate – that is the amount it can flex before being permanently deformed.

The odd tent brand may use 7075 aluminium alloy for its tent poles, which is an inherently stiffer alloy than 7001, so will not deflect as much under duress. However, this property also makes for a more brittle tent pole. So although it may be more rigid, it will more likely fracture than flex in more extreme weather conditions. Our aluminium trekking poles are made from 7075 aluminium alloy, as rigidity is more important than flex in a trekking pole (STATION13 trekking Poles). Our trekking poles are of course also fabricated from substantially thicker and stronger aluminium tubing than that of tent poles.

Be aware, some cheaper tents may also use 6000 series aluminium alloy tent poles. This is a less costly aluminium alloy, but it is inherently weaker than 7000 series aluminium alloy when used for tent poles. 6000 series alloy tends to have much less flex and be far more rigid, so again, more likely to fracture or snap than flex when stressed. By way of emphasising this, most lightweight aluminium tent pegs are made from 6000 series aluminium alloy, as are many aluminium bicycle frames, where the greater flex of 7000 series aluminium alloy would be less desirable.

We looked long and hard at the pros and cons of various alloys but ultimately we settled on 7001 alloy, because even if a tent pole was to flex to a point that it became slightly deformed, we see this as a better option than it fracturing or completely snapping, which may be far more likely with 7075 alloy. And, after all, if DAC are happy with 7001 aluminium alloy, then who are we to argue.

Now, whereas the likes of DAC manufacture various versions of lightweight tent poles, using varied manufacturing techniques to add strength, or to shave off grams here and there in order to reduce the overall weight of their poles, we have stuck to the more universal tent pole construction.

By this I mean that our ProFlex tent poles use a standard aluminium press-fit insert to connect one pole to the next. And unless your tent poles are manufactured by DAC, Easton or Yunan (that may use a different connecting method, and/or be of an odd size), then your tent poles will very likely be the same.

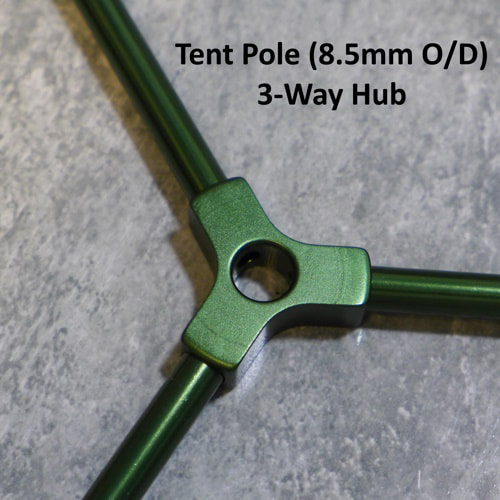

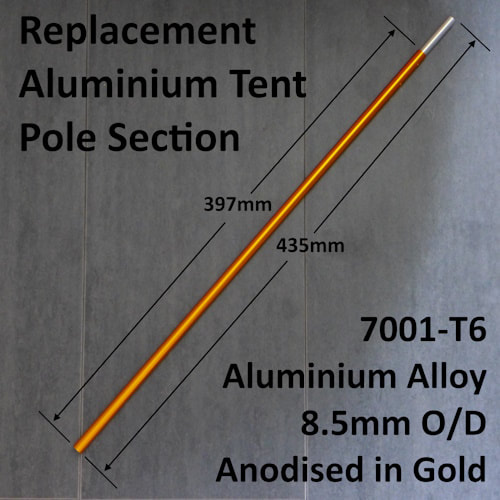

These are the 8.5mm tent pole products available from us

We can now supply complete tent poles, with some tent poles made to your personal requirements, along with some tent pole fittings.

- Aluminium Alloy 7001 T6 tent poles complete (up to 6m)

- Aluminium Tent Pole End Plugs: These are the parts at the end of tent poles that fit into a metal eyelet.

- Aluminium Tent Pole End Stops: These are used at one end of tent poles with tents that use a closed-end sleeve as apposed to a strap and eyelet.

- 3-Way Aluminium Alloy Hub: (as used in our SAGE tent where 3 tent poles converge and join).

- Angled Tent Pole Section (135 degree bend) - Both male ends.

- Aluminium Alloy Repair Sleeve: For 8.5mm tent poles. These sleeves slide over a broken or damaged tent pole to provide an emergency temporary fix.

- Aluminium Tent Pole Inserts: These are used to connect tent pole sections together (one end will be permanently fixed into one tent pole providing a male fitting to mate with a corresponding female (open end) tent pole section.

- Shock Cord: Sold in 6 metre lengths. Used to keep in place and hold tent pole sections together.

NOTE: We can cut individual pole sections down to meet your specific requirements and also provide custom tent pole lengths. Any queries just email us at [email protected] or use our CONTACT FORM.

We also have GOLD, RED and GREEN 8.5mm replacement tent poles and tent pole sections available.

Just CLICK on the images to be taken to our relevant eBay listings.

Just CLICK on the images to be taken to our relevant eBay listings.