STATION13 Z-Pad & RIPPLE

Lightweight Folding Sleeping Pads

If paying via Credit Card click 'HERE' to go directly to our Z-Pad purchase page

or 'HERE' to go directly to our eBay RIPPLE listing

...or just click on the images!

or 'HERE' to go directly to our eBay RIPPLE listing

...or just click on the images!

|

Z-Pad Features:

|

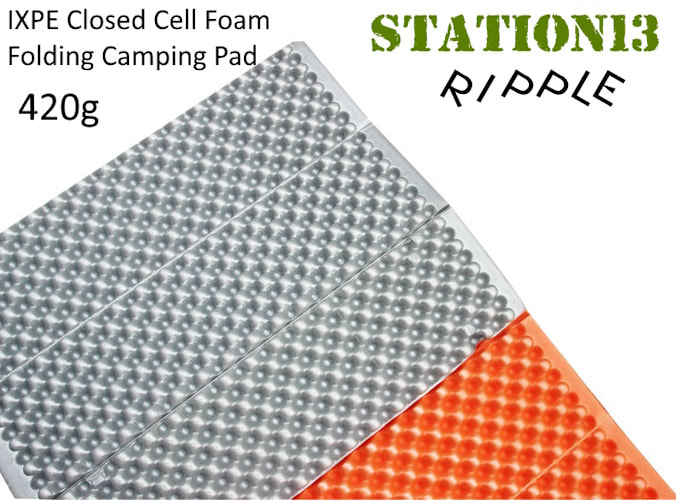

RIPPLE Features:

|

Click 'HERE' to go directly to our Z-Pad purchase page

or 'HERE' to go directly to our eBay RIPPLE listing.

or 'HERE' to go directly to our eBay RIPPLE listing.

When I first started camping and I was much younger and much fitter, the only lightweight sleeping options for backpackers were solid closed-cell foam pads. They offer some protection from the cold ground and evened out some lumps and bumps, but provided next to nothing in terms of comfort. Yet that was all that was available and somehow we coped. Nowadays however, with older bones and a few aching joints, I could not even consider sleeping on such a pad. That said, closed-cell foam pads still have their place in lightweight camping and backpacking.

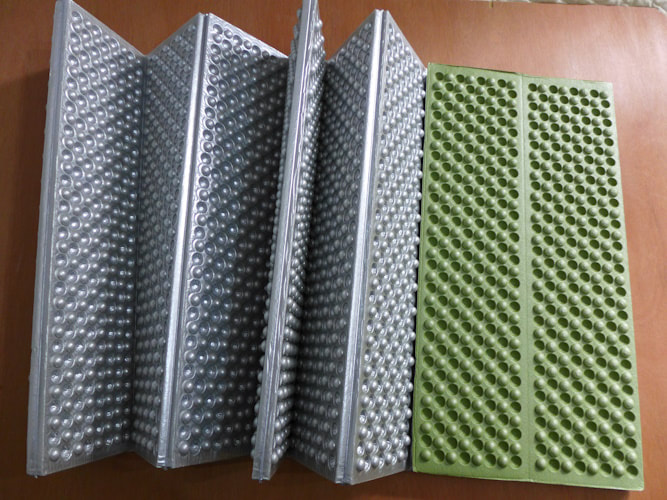

The original closed-cell foam pads (and you can still get them) rolled out and rolled up. The only issue here is that they don’t always unroll very well and do tend to try to re-roll back up once you lay them out. This does not happen with the new folding Z-Pad types of closed-cell foam pads which neatly fold up and neatly fold out.

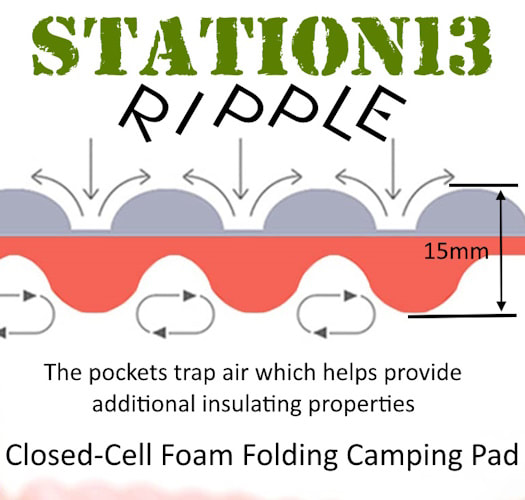

Another difference between the original closed-cell roll up foam pads and the more modern folding type is that whereas the old style were solid (usually 6-10mm thick), the modern folding pads have corrugations or dimples that not only add depth and so give slightly more cushioning, but also naturally provide air pockets that can effectively provide additional insulation.

Overall thickness - that is the depth of the more modern folding pads with peaks and troughs - is usually around the 15 - 20mm mark, though you can get thicker. Although the peaks and troughs will flatten out somewhat when in use, these pads do tend to be marginally more comfortable than the original solid roll-up style foam pads.

Modern materials and manufacturing techniques have made the closed-cell foam folding pads more durable and slightly lighter than the original roll up foam pads, but size-wise not too much has changed.

Apart from the lack of any real comfort, the other major issue with any closed-cell foam pad is that they are bulky. Put one of these pads in your rucksack and you will have little room for anything else, however, due to their relatively lightweight, strapping one onto the outside of your rucksack presents very little problem.

So let’s now talk about the good points of these closed-cell foam pads. Well, the biggy is that you can’t easily break them – there is nothing to puncture and they are pretty durable – so at the very least they will always provide you with insulation from cold ground, and maybe a modicum of comfort, which is more than can be said for a deflated air mattress. They are totally waterproof and folding versions can also be used as sit pads.

But where we find these pads really come into their own is when used in winter as an additional insulator from the cold ground underneath an inflatable air mattress. I say winter, but we now actually carry a folding closed-cell foam pad with us for camping year round. The additional 350-400 grams is negated by pros they offer. Firstly, we do at least have something to sleep on keeping us off the ground should our inflatable air mattress get a puncture. Secondly, is the fact that we are less likely to actually puncture an air mattress if a closed-cell foam pad is underneath it.

The actual manufacturing materials and techniques can vary slightly with these closed-cell foam pads, so do bear this in mind. Some closed-cell foam pads are made from the more dated EVA, whilst others are now made from the more modern XPE and IXPE.

EVA stands for Ethylene-Vinyl Acetate, XPE stands for Cross-Linked Polyethylene. To look at, the difference is not that obvious, but the dead giveaway is initial smell. EVA pads tend to have quite a strong chemical smell (though this does disappear over a couple of weeks), whereas XPE pads on the other hand have little to no smell, are completely non-toxic, and are slightly more fire retardant. EVA is also less resilient than XPE so tends to have a shorter life. Both are very good insulators, both are completely imperious to water or liquids, will not absorb moisture, and both are very buoyant. XPE and IXPE pads are relatively stronger and more durable due to the cross-link structure of their molecules. XPE is more resistant to chemicals, abrasion and extreme heat than EVA, and whilst not being quite so elastic, XPE does tend to spring back to its original shape faster and better than EVA. It is also worth bearing in mind that XPE and IXPE pads are also made via a greener, far more environmentally friendly manufacturing process.

The difference between XPE and IXPE is nothing to do with the material used, but rather the manufacturing process. Both are cross-linked polyethylene, but the ‘I’ stands for ‘Irradiated’ and is a cross-linking technique using an electron accelerator to form a yet stronger cross-linking bond. As well as being slightly stronger, this gives a more dense, slightly firmer pad.

XPE and IXPE pads are more expensive to produce than the more dated EVA pads, but as mentioned the manufacturing process is far more environmentally friendly and they are more resilient.

Though slightly more costly, closed-cell foam pads with an aluminised backside do provide a greater potential warmth than those without, as the aluminium reflects body heat back up away from the colder ground. The idea is that in colder temperatures you would sleep with the aluminised side up, and in warm, summer weather conditions when you might be overly hot, you would turn the aluminised side down.

When it comes to insulation from the cold ground and when used alone, with an R-value of 1.7 and 1.9, these pads are best suited just to summer use. However, as already mentioned, as they are not the most comfortable of things to sleep on, their greater value can be when used in conjunction with other pads and mattresses to not only add an additional layer of insulation from cold ground, but also protect more damage sensitive (and often expensive) air mattresses and self-inflating mattresses from potential punctures.

The original closed-cell foam pads (and you can still get them) rolled out and rolled up. The only issue here is that they don’t always unroll very well and do tend to try to re-roll back up once you lay them out. This does not happen with the new folding Z-Pad types of closed-cell foam pads which neatly fold up and neatly fold out.

Another difference between the original closed-cell roll up foam pads and the more modern folding type is that whereas the old style were solid (usually 6-10mm thick), the modern folding pads have corrugations or dimples that not only add depth and so give slightly more cushioning, but also naturally provide air pockets that can effectively provide additional insulation.

Overall thickness - that is the depth of the more modern folding pads with peaks and troughs - is usually around the 15 - 20mm mark, though you can get thicker. Although the peaks and troughs will flatten out somewhat when in use, these pads do tend to be marginally more comfortable than the original solid roll-up style foam pads.

Modern materials and manufacturing techniques have made the closed-cell foam folding pads more durable and slightly lighter than the original roll up foam pads, but size-wise not too much has changed.

Apart from the lack of any real comfort, the other major issue with any closed-cell foam pad is that they are bulky. Put one of these pads in your rucksack and you will have little room for anything else, however, due to their relatively lightweight, strapping one onto the outside of your rucksack presents very little problem.

So let’s now talk about the good points of these closed-cell foam pads. Well, the biggy is that you can’t easily break them – there is nothing to puncture and they are pretty durable – so at the very least they will always provide you with insulation from cold ground, and maybe a modicum of comfort, which is more than can be said for a deflated air mattress. They are totally waterproof and folding versions can also be used as sit pads.

But where we find these pads really come into their own is when used in winter as an additional insulator from the cold ground underneath an inflatable air mattress. I say winter, but we now actually carry a folding closed-cell foam pad with us for camping year round. The additional 350-400 grams is negated by pros they offer. Firstly, we do at least have something to sleep on keeping us off the ground should our inflatable air mattress get a puncture. Secondly, is the fact that we are less likely to actually puncture an air mattress if a closed-cell foam pad is underneath it.

The actual manufacturing materials and techniques can vary slightly with these closed-cell foam pads, so do bear this in mind. Some closed-cell foam pads are made from the more dated EVA, whilst others are now made from the more modern XPE and IXPE.

EVA stands for Ethylene-Vinyl Acetate, XPE stands for Cross-Linked Polyethylene. To look at, the difference is not that obvious, but the dead giveaway is initial smell. EVA pads tend to have quite a strong chemical smell (though this does disappear over a couple of weeks), whereas XPE pads on the other hand have little to no smell, are completely non-toxic, and are slightly more fire retardant. EVA is also less resilient than XPE so tends to have a shorter life. Both are very good insulators, both are completely imperious to water or liquids, will not absorb moisture, and both are very buoyant. XPE and IXPE pads are relatively stronger and more durable due to the cross-link structure of their molecules. XPE is more resistant to chemicals, abrasion and extreme heat than EVA, and whilst not being quite so elastic, XPE does tend to spring back to its original shape faster and better than EVA. It is also worth bearing in mind that XPE and IXPE pads are also made via a greener, far more environmentally friendly manufacturing process.

The difference between XPE and IXPE is nothing to do with the material used, but rather the manufacturing process. Both are cross-linked polyethylene, but the ‘I’ stands for ‘Irradiated’ and is a cross-linking technique using an electron accelerator to form a yet stronger cross-linking bond. As well as being slightly stronger, this gives a more dense, slightly firmer pad.

XPE and IXPE pads are more expensive to produce than the more dated EVA pads, but as mentioned the manufacturing process is far more environmentally friendly and they are more resilient.

Though slightly more costly, closed-cell foam pads with an aluminised backside do provide a greater potential warmth than those without, as the aluminium reflects body heat back up away from the colder ground. The idea is that in colder temperatures you would sleep with the aluminised side up, and in warm, summer weather conditions when you might be overly hot, you would turn the aluminised side down.

When it comes to insulation from the cold ground and when used alone, with an R-value of 1.7 and 1.9, these pads are best suited just to summer use. However, as already mentioned, as they are not the most comfortable of things to sleep on, their greater value can be when used in conjunction with other pads and mattresses to not only add an additional layer of insulation from cold ground, but also protect more damage sensitive (and often expensive) air mattresses and self-inflating mattresses from potential punctures.